Burner

As the most important auxiliary equipment in boiler equipment, the quality of the burner will directly affect the operating efficiency of the boiler and the emission of nitrogen oxides. Fangkuai boiler is an integrated (split) burner designed and manufactured in accordance with relevant international and domestic standards. It adopts a multi-stage combustion method and covers a wide range of furnace types. It can be used in water tube boilers, fire tube boilers, modular boilers, and central boilers. In boilers such as fired boilers.

Deaerator

The deaerator is one of the key equipment in the boiler and heating system. It is mainly composed of the deaeration tower head and the deaeration water tank, as well as the connecting pipe and external parts. If the deaerator's deaeration capacity is poor, it will cause serious corrosion effects on the boiler's water supply pipes, economizers and other auxiliary equipment, and the economic loss caused will be tens or even hundreds of times the cost of the deaerator. For this reason, Everyone must pay attention to the quality selection of deaerators.

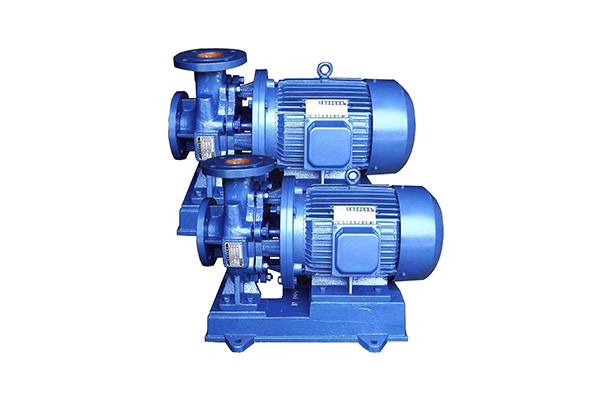

Deaerator water pump

The deaerator water pump needs to be used in conjunction with a deaerator in order to perform a good deaeration function in the boiler equipment. Generally speaking, the selection of deaerator pumps should not only combine the flow-head curve, but also simulate the working curve after parallel connection through certain selection software, and leave a certain margin. Therefore, in the two When the deaerator pumps are connected in parallel, 5-10% of the space can be reserved according to experience, which requires the boiler engineer to have certain technical experience.

Circulating pump

The circulating water pump refers to the circulating liquid pump used in the boiler device to transport the reaction, absorption, separation, and regeneration of the absorption liquid. Its head is low, it is only used to overcome the pressure drop of the circulation system, and a low head pump can be used. The flow rate of the circulating water pump is medium. Under stable working conditions, the flow rate of the pump changes relatively little. Its head is small and low, just to overcome the pressure drop of the circulatory system. A low-lift pump can be used.

CIRCULATION PUMPS

A water pump is a mechanical accessory that transports liquids or pressurizes liquids. It transfers the mechanical energy of the prime mover or other external energy to the liquid to increase the energy of the liquid. The main liquids used to transport include water, oil, acid and alkali, emulsion, Suspension emulsion and liquid metal, etc.; can also transport liquids, gas mixtures and liquids containing suspended solids. The technical parameters for judging the performance of a water pump include flow, suction, lift, shaft power, water power, and efficiency.